Inter-floor leakage is probably the most common problem faced by residents in non-landed strata homes. It is also a problem that poses the biggest headache, as the source of the leak is difficult to identify and fix.

Wayne Restoration and Engineering Sdn Bhd principal Kuan You Wai tells EdgeProp.my that one of the main contributing causes of inter-floor leakage problems is the lack of knowledge or expertise in dampness prevention.

“Inter-floor leakage means dampness in buildings caused by water leakage and condensation. The problems need to be solved as soon as possible, otherwise it will cause secondary damage such as indoor microbial growth and concrete degradation,” says the specialist contractor in inter-floor leakage.

Water leakage can’t be avoided as long as water is present including the water brought into the building through pipes and faucets, waste pipes that drain out used water and rain water.

Any leakage from pipes or cavities in the buildings would cause water to pool and penetrate into the concrete floor. As dampness increases, it leads to degradation of the concrete floor and corrosion of the reinforcement steel bars within.

Kuan notes that the degradation will cause cracks on the floor or wall, which offer passages for water ingress, thus worsening the problem.

Reasons for water leakage

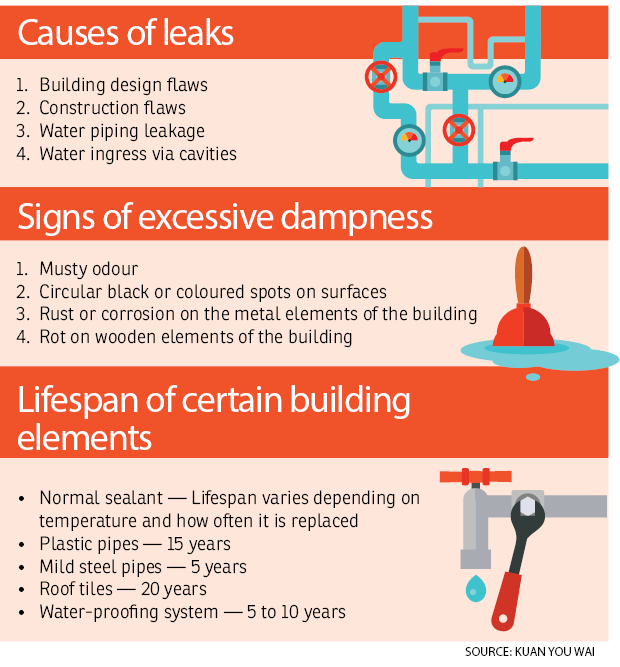

There are a number of causes that can lead to water ingress and dampness in buildings. Building flaws caused during construction could be the beginning of the problem.

“At the design stage, the basic and mandatory requirements for building practices are outlined in the Uniform Building By-laws 1984. In a country blessed by non-availability of major natural disasters, many good practices are compromised by cost-cutting or a trendy look,” he adds.

For instance, window ledges above windows are normally provided in houses in Malaysia. They serve as caps and prevent water ingress via surface tension. However, the ledges are not compulsory and a flat facade is common in European countries (which have less rain). In Malaysia, such a design would cause a widespread case of leakage.

During construction, premature removal of formwork — especially with the excessive heat from the Malaysian weather — during the concrete placement could cause cracks.

“Such erroneous practices can contribute to the development of cracks on the concrete structures and roofs,” says Kuan.

Besides this, weathering and cracks on flat roofs and external facades have been posing major headaches among building managers in Malaysia, he adds.

Under the intense sun and pummelled by heavy rain, the building envelopes suffer from differential thermal stress at different components. For instance, coefficient of thermal expansion of concrete is almost double of clay bricks.

In other words, under the exposure to the sun, concrete expands twice the speed of bricks, which causes crack lines on the roofs and the joints between the concrete slabs and brick walls at the highest floor.

Besides thermal movement, building envelopes crack due to a number of other reasons, such as moisture movement, creep, wind pressure and settlement.

Kuan says the direction where the house faces and wind speed could also contribute to water leakage, as strong winds add force and push water through cavities while misaligning roof tiles.

Other weathering factors like carbonation, chloride, acid rain, ozone and other pollutants also contribute substantially to the propagation of cracking, degradation of concrete, as well as corrosion of metal components such as gutters and steel pipes.

Fixing the problem

“We must first of all identify the source of the leak and understand the degradation mechanism before remediation actions are taken,” stresses Kuan.

For the crack lines caused by temperature, turning the crack lines into control joints would be feasible. For smaller crack lines, elastomeric coating could bridge the crack lines and limit the movement of the crack lines.

“In many instances, building owners and contractors repair and maintain buildings based on the lowest acquisition costs practicable. Nevertheless, opting for quick fixes instead of addressing the degradation mechanism always brings about more frequent and higher maintenance costs due to the ease of wear and tear,” he notes.

On the other hand, the Ministry of Urban Wellbeing, Housing and Local Government recommends a European standard in the repair of building structures known as EN1504. It is a holistic approach that looks into the chemistry of concrete degradation, repair and protection with the most reasonable life-cycle costs.

Kuan also points out that all building elements have their respective service lifespan and the property management and property owners should inspect the condition of their properties regularly and mend a problem as soon as possible.

For instance, he explains, normal sealants need to be replaced regularly while plastic pipes can typically last 15 years. Compared with plastic pipes, mild steel pipes have shorter lifespan of around five years.

Roof tiles have a lifespan of around 20 years and waterproofing systems only last around five to 10 years.

“Life-cycle management denotes refurbishment or replacement of these elements before they cause subsequent damage to other building elements. It also denotes consideration for the selection of materials and methods based on full ownership costs rather than cheaper acquisition costs but higher maintenance costs later in the life cycle,” Kuan says.

Severe consequence of neglect

Leaving leakage problems unattended for years could cause severe consequences as it could affect the building structure.

“Building materials — be it masonry, metal, polymer or timber — suffer from loss of strength and functionality when exposed to excessive dampness,” he explains.

Besides this, biological contamination such as mold, dust mites, bugs, protozoa and bacteria can multiply excessively.

“These organisms emit microbial volatile organic compound, mycotoxins, spores and waste that can cause deterioration of the indoor air-quality and cause allergy and other ailments,” Kuan warns.

This story first appeared in EdgeProp.my pullout on Dec 8, 2017. Download EdgeProp.my pullout here for free.

TOP PICKS BY EDGEPROP

UNA SERVICED APARTMENT

Jalan Peel, Kuala Lumpur

Tropicana Golf & Country Resort

Tropicana, Selangor